Manufacturing

About Keeping Manufacturing

As a leading manufacturer of air purifiers, our company is committed to delivering high-quality, reliable, and innovative air purification solutions. Our manufacturing facilities are equipped with advanced production lines, precision testing equipment, and strict quality control systems to ensure each unit meets international standards for performance and safety. From design to final assembly, every stage of our manufacturing process is guided by a focus on efficiency, environmental responsibility, and customer satisfaction. Our experienced engineering and production teams work closely to develop products that combine cutting-edge filtration technology with user-friendly design, helping to create cleaner, healthier indoor environments worldwide.

Uncompromising Quality Through Rigorous Control

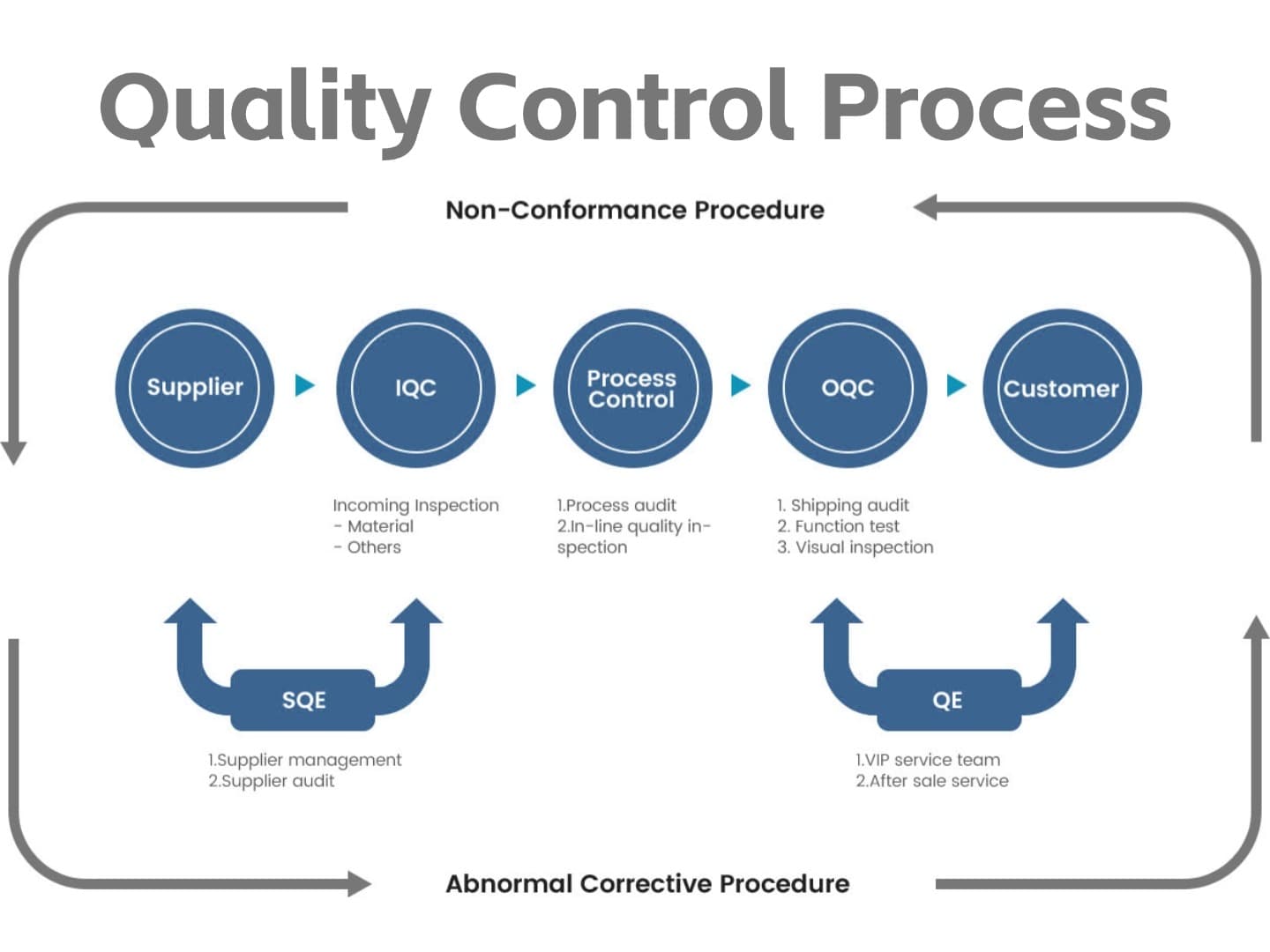

At the heart of our manufacturing philosophy lies a strong commitment to quality. We have established a comprehensive quality control system that oversees every step of the production process—from raw material inspection and in-line checks to final product testing.

Quality Control Process

The quality management process ensures that each product meets performance, safety, and reliability standards.

Expert Product Testing

Expert Testing is a critical phase in quality assurance, leveraging technical authority and practical experience to safeguard product competitiveness.

Completed Product Test

Final inspection is the last critical step to ensure product quality meets standards.

Embracing Automation for Precision and Efficiency

Our manufacturing facility leverages advanced automation technologies to streamline the entire production process of air purifiers. From component assembly to performance testing, our automated systems ensure consistent quality, reduced lead times, and increased production capacity.

.jpg&w=1920&q=75)

.jpg&w=1920&q=75)

.jpg&w=1920&q=75)

.jpg&w=1920&q=75)

.jpg&w=1920&q=75)

.jpg&w=1920&q=75)